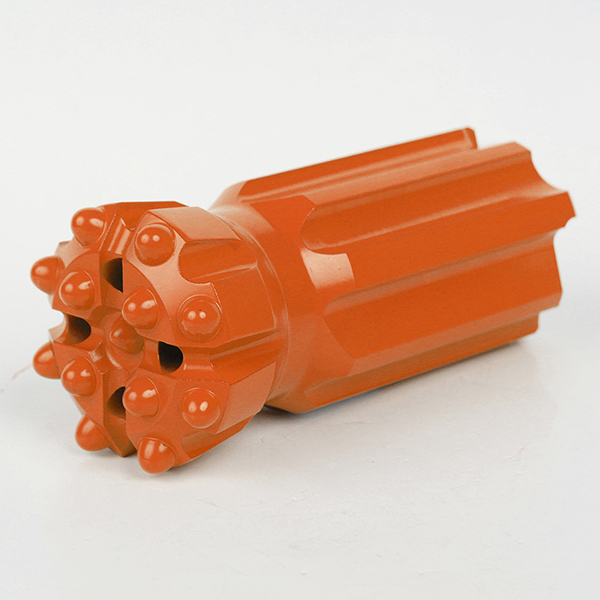

The choice of mine tapered button bit

According to the nature of the rock, choose the appropriate tapered button bit for cemented carbide mines. Generally speaking, for rock with high hardness, tapered bit provided by alloy with relatively low hardness is selected, otherwise, tapered bit of alloy with relatively high hardness is selected. For extremely hard rock, if the power of the rock drill is high, the three-blade or cross tapered bit can be used. At this time, in order to facilitate unloading, the taper hole of the tapered button bit can be selected at 11° or 12°. For medium-hard rock with good integrity, in order to improve work efficiency and reduce costs, the tapered button bit can be selected.

| Technical Parameters | ||||||

| DIAMETER | BUTTONS | FLUSHING | CARBIDE | FACE | ||

| MM | IN | GAUGE NO/ SIZE | FRONT NO/ SIZE | HOLE | PROFILE | PROFILE |

| 32 | 1 1/4″ | 5×7 | 2×7 | IF1G | Parabolic | Flat |

| 36 | 1 13/32″ | 5×8 | 2×7 | 2F1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 1F2G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F 1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F1G | Conical | Flat |

| 40 | 1 9/16″ | 5×9 | 2×8 | 2F 1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F 1G | Parabolic | Flat |