Common safety protection functions of air compressors

1. Motor overload protection

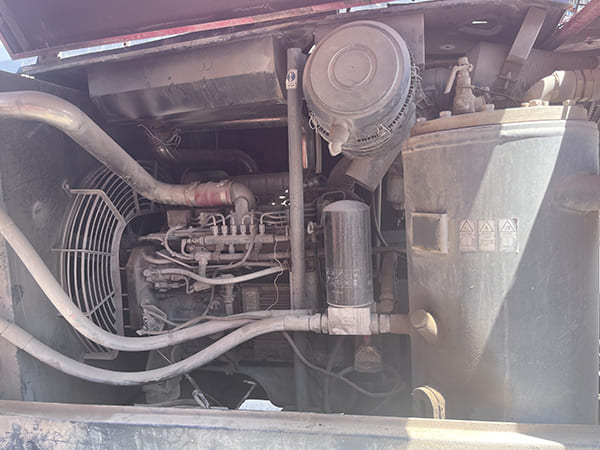

There are two main motors in the screw air compressor system, one is the main motor driven by the air compressor; the other is the cooling fan motor. Under normal conditions, the operating current of the motor will not exceed the rated value.

10% of the constant current. When the motor running current exceeds the upper limit set by the power protection device, the overload current protection device will automatically cut off the main current and the air compressor will stop.

2. Excessive exhaust pressure protection

When the system exhaust pressure exceeds the rated exhaust pressure by more than 0.5bar, the system will automatically cut off the power supply. When the air consumption is 0 and the discharge volume is less than the intake air volume, the system pressure will rise rapidly, causing the safety valve to act and release.

gas. In order to avoid the frequent action of the safety valve and increase the safety factor of the machine, it is necessary to set this protection.

3. Low oil pressure protection

When the system oil pressure is lower than 0.15-0.2mpa, the pressure switch will send a signal to stop the motor to protect the main engine from being burnt out due to lack of oil.

8. Filter blockage protection

When the air filter element, oil filter element and oil separator of the screw air compressor are blocked, it will be displayed on the control panel. When there is a fault indication on the panel, it means that the filter is clogged and needs to be replaced with a new filter element as soon as possible.