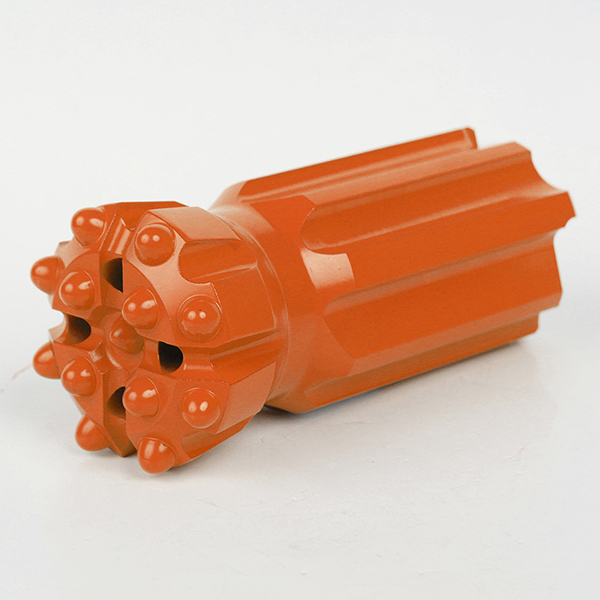

When using the tapered button bit and the drill rod, first check whether the drill tail of the tapered drill rod is flat, whether the taper tip and the taper hole meet the requirements, whether the cutting edge of the tapered button bit is damaged, whether the water hole is not unblocked, and whether the air pressure water Whether the pressure is enough, the tapered button bit is strictly forbidden to collide with the alloys between the tapered button bits. When drilling holes, it should be noted that the wind must be light and light, that is, the wind pressure should be drilled with a small amount first, and then the wind pressure can be gradually adjusted to normal after the drilling is stable. When withdrawing the drill, try to reverse the drill and avoid forcibly knocking and pulling as much as possible, so as not to damage the tapered button bit or the drill rod, resulting in early scrapping.

| Technical Parameters | ||||||

| DIAMETER | BUTTONS | FLUSHING | CARBIDE | FACE | ||

| MM | IN | GAUGE NO/ SIZE | FRONT NO/ SIZE | HOLE | PROFILE | PROFILE |

| 32 | 1 1/4″ | 5×7 | 2×7 | IF1G | Parabolic | Flat |

| 36 | 1 13/32″ | 5×8 | 2×7 | 2F1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 1F2G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F 1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F1G | Conical | Flat |

| 40 | 1 9/16″ | 5×9 | 2×8 | 2F 1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F 1G | Parabolic | Flat |